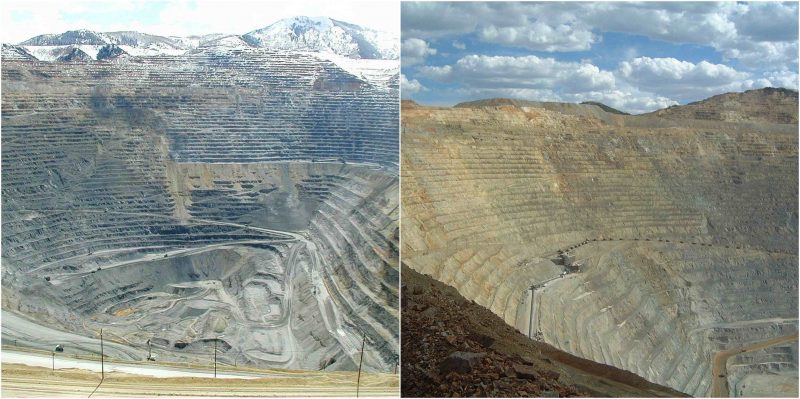

The Bingham Canyon Mine, more commonly known as Kennecott Copper Mine among locals, is an open-pit mining operation extracting a large porphyry copper deposit southwest of Salt Lake City, Utah, USA, in the Oquirrh Mountains.

The mine is the largest man-made excavation in the world, and is owned by Rio Tinto Group, an international mining and exploration company headquartered in the United Kingdom. The copper operations at Bingham Canyon Mine are managed through Kennecott Utah Copper Corporation which operates the mine, a concentrator plant, a smelter, and a refinery.

The mine has been in production since 1906, and has resulted in the creation of a pit over 0.6 miles (970 m) deep, 2.5 miles (4 km) wide, and covering 1,900 acres (770 ha). It was designated a National Historic Landmark in 1966 under the name Bingham Canyon Open Pit Copper Mine. The mine experienced a massive landslide in April 2013 and a smaller slide in September 2013.

Minerals, in the form of copper ore, were first discovered in Bingham Canyon in 1848 by two brothers, Sanford and Thomas Bingham, sons of Erastus Bingham, Mormon pioneers of September 1847, who grazed their cattle there.

They reported their find to their leader, Brigham Young, who advised against pursuing mining operations because the survival and establishment of settlements was of paramount importance at that time. The brothers applied themselves to that purpose as directed and did not stake a claim. In 1850, the Bingham family went to settle what is now Weber County, leaving the canyon still today known by their name.

It was not until 17 Sept. 1863 that extraction of ore began and the potential of the canyon’s mineral resources began to be widely recognized. That was when George B. Ogilvie and 23 others “located the West Jordan claim”, soon followed by the Vidette claim. At first, mining was confined to placer gold, lead-silver and copper-gold. Porphyry copper required processing and a railroad, which reached the canyon in 1873.

Enos Andrew Wall started working claims in 1887. His extensive tunnels and test pits, on his 200 acres, indicated ore containing 2% copper.

The canyon’s 19th Century mines were relatively small, but it wasn’t until the end of the century that very large-scale exploitation of the canyon’s ore bodies began to develop with open-pit mining.

In 1896, Samuel Newhouse and Thomas Weir acquired the Highland Boy Mine, which was rich in copper, silver and gold. Together they formed the Utah Consolidated Gold Mines, Ltd. with English investors. They then formed the Boston Consolidated Gold and Copper Co., Ltd., for development of low-grade copper ore adjacent to the Utah Copper Company site.

Continue to page 2

Another significant development took place in 1903, when Daniel C. Jackling and Enos A. Wall organized the Utah Copper Company. Utah Copper immediately began construction of a pilot mill atCopperton, just beyond the mouth of the canyon, and the company actually started mining in 1906.

The success of Utah Copper in mining the huge but low-grade porphyry copper type ore body at Bingham Canyon was based on Jacklin’s 1904 decision to use open-pit mining, steam shovels and the railroad.

The mine became a showplace for “railroad-pit operations” and the industrial complex defined by the mine and the ASARCO smelting operation made it the “largest industrial mining complex in the world” by 1912.

Utah Copper and Boston Consolidated merged after their separate surface operations approached each other in 1906. The Kennecott Copper Corporation, established to operate mines in Kennecott, Alaska, purchased a 25 percent financial interest in Utah Copper in 1915, which they increased to 75 percent in 1923.

Bingham’s Canyon mine expanded rapidly, and by the 1920s the region was a beehive of activity. Some 15,000 people of widely varying ethnicity lived in the canyon, in large residential communities constructed on the steep canyon walls.

The population declined rapidly as mining techniques improved, and several of the mining camps were swallowed up by the ever-expanding mine. By 1980, when Lark was dismantled, only Copperton, at the mouth of Bingham Canyon and with a population of 800, remained.

The 21 separate mining operations in existence by 1911 were consolidated into two in 1970: Kennecott and The Anaconda Minerals Company. In 1985 open-pit mining operations were halted by Kennecott’s Utah Copper. In 1986, Kennecott discovered gold in nearby Barney’s Canyon.

KCC was purchased by Sohio in 1981 and the mine reopened in 1987 after BP Minerals purchased the assets. In 1989 the Rio Tinto Group acquired the asset, who modernized the mine, mill and smelter.

The open-pit owners replaced an antiquated 1000-car railroad with conveyor belts and pipelines for transporting the ore and waste, which reduced costs by nearly 30% and returned the operation to profitability

At 9:30 pm on April 10, 2013, a landslide occurred at the mine. It was the largest non-volcanic landslide in the history of North America, and around 65–70 million cubic meters (2.3×109–2.5×109 cu ft) of dirt and rock thundered down the side of the pit. Understanding that the mine’s steep walls made it a high risk for landslides, an interferometric radar system had been installed to monitor the ground’s stability.

As a result of warnings produced by this system, mining operations were shut down the previous day in anticipation of the slide. There were no injuries. The massive slide is expected to cut production of mined copper by 100,000 tonnes (110,000 short tons). A second slide caused an evacuation of 100 workers on September 11, 2013.