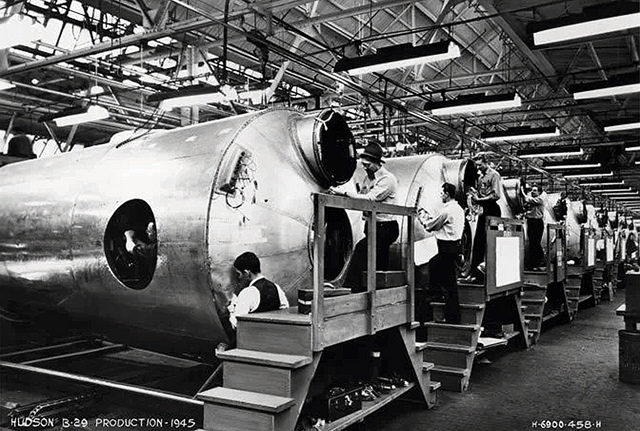

The B-29 was the original production version of the Superfortress. Since the new bomber was urgently needed, the production design was developed in tandem with the service testing. In fact, the first B-29 was completed only two months after the delivery of the first YB-29. Forty-six B-29s of this variant, built by the Glenn L. Martin Company at its Omaha plant, were used as the aircraft for the atomic bomb missions, modified to Silverplate specifications.

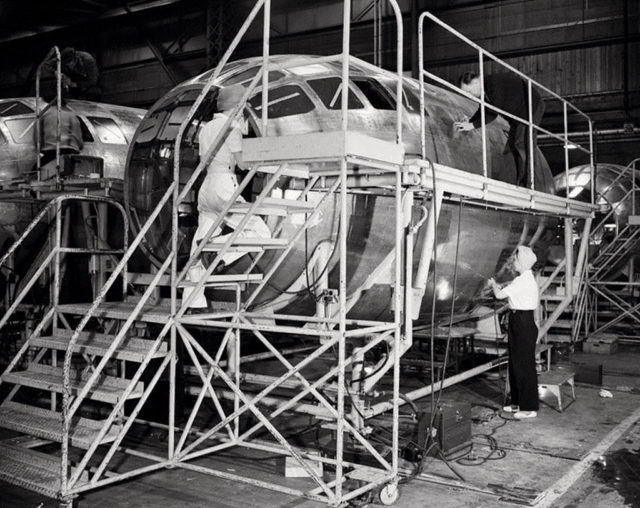

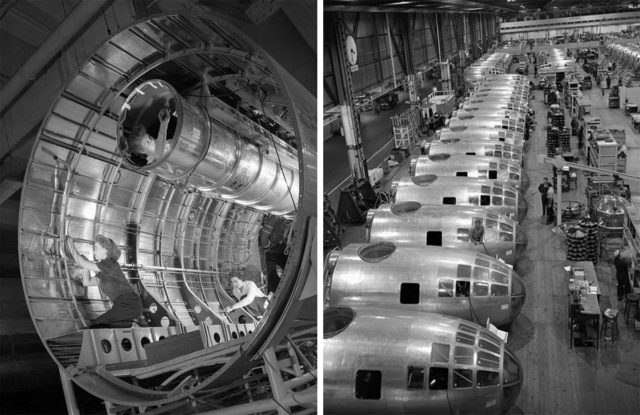

Manufacturing the B-29 was a complex task. It involved four main-assembly factories: a pair of Boeing operated plants at Renton, Washington (Boeing Renton), and Wichita, Kansas (now Spirit AeroSystems), a Bell plant at Marietta, Georgia (“Bell-Atlanta”), and a Martin plant at Omaha, Nebraska (“Martin-Omaha” – Offutt Field). Thousands of subcontractors were involved in the project. The first prototype made its maiden flight from Boeing Field, Seattle on 21 September 1942. The combined effects of the aircraft’s highly advanced design, challenging requirements and immense pressure for production hurried development and caused setbacks. All photos: Sms_S/Flickr/Under CC BY 2.0

The second prototype, which, unlike the unarmed first, was fitted with a Sperry defensive armament system using remote-controlled gun turrets sighted by periscopes, first flew on 30 December 1942. This flight being terminated due to a serious engine fire. On 18 February 1943, the second prototype, flying out of Boeing Field in Seattle, experienced an engine fire and crashed. The crash killed Boeing test pilot Edmund T. Allen and his 10-man crew, 20 workers at the Frye Meat Packing Plant, and a Seattle firefighter.

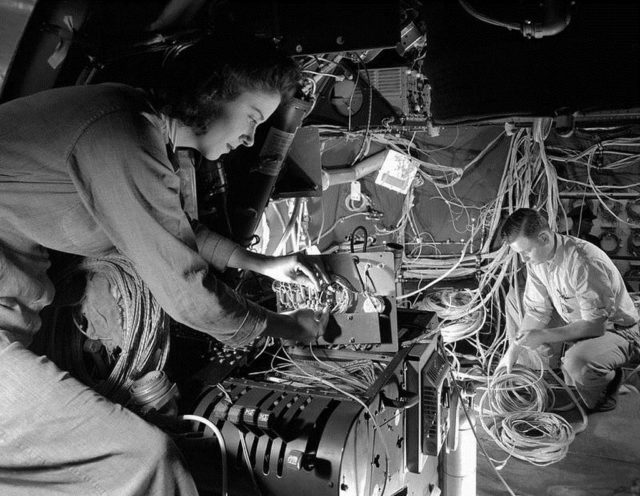

Changes to the production craft came so often and so fast that in early 1944, B-29s flew from the production lines directly to modification depots for extensive rebuilds to incorporate the latest changes. AAF-contracted modification centers and its own air depot system struggled to cope with the scope of the requirement. Some facilities lacked hangars capable of housing the giant B-29, requiring outdoor work in freezing cold weather, further delaying necessary modification.

By the end of 1943, although almost 100 aircraft had been delivered, only 15 were airworthy. This prompted an intervention by General Hap Arnold to resolve the problem, with production personnel being sent from the factories to the modification centers to speed the availability of sufficient aircraft to equip the first Bomb Groups in what became known as the “Battle of Kansas.” This resulted in 150 aircraft being modified in the six weeks between 10 March and 15 April 1944.

The most common cause of maintenance headaches and catastrophic failures were the engines. Although the Wright R-3350 Duplex-Cyclone radial engines later became a trustworthy workhorse in large piston-engined aircraft, early models were beset with dangerous reliability problems. This problem was not fully cured until the aircraft was fitted with the more powerful Pratt & Whitney R-4360 “Wasp Major” in the B-29D/B-50 program, which arrived too late for World War II. Interim measures included cuffs placed on propeller blades to divert a greater flow of cooling air into the intakes which had baffles installed to direct a stream of air onto the exhaust valves. Oil flow to the valves was also increased, asbestos baffles installed around rubber push rod fittings to prevent oil loss, thorough pre-flight inspections made to detect unseated valves, and frequent replacement of the uppermost five cylinders (every 25 hours of engine time) and the entire engines (every 75 hours).

Pilots, including the present-day pilots of the Commemorative Air Force’s Fifi, one of the last two remaining flying B-29s, describe flight after takeoff as being an urgent struggle for airspeed (generally, flight after takeoff should consist of striving for altitude). Radial engines need airflow to keep them cool, and failure to get up to speed as soon as possible could result in an engine failure and risk of fire. One useful technique was to check the magnetos while already on takeoff roll rather than during a conventional static engine-runup before takeoff.

In wartime, the B-29 was capable of flight at altitudes up to 31,850 feet (9,710 m), at speeds of up to 350 mph (560 km/h) (true airspeed). This was its best defense because Japanese fighters could barely reach that altitude, and few could catch the B-29 even if they did get high enough. Only the heaviest of anti-aircraft weapons could reach it, and since the Axis forces did not have proximity fuzes, hitting or damaging the aircraft from the ground in combat proved difficult.