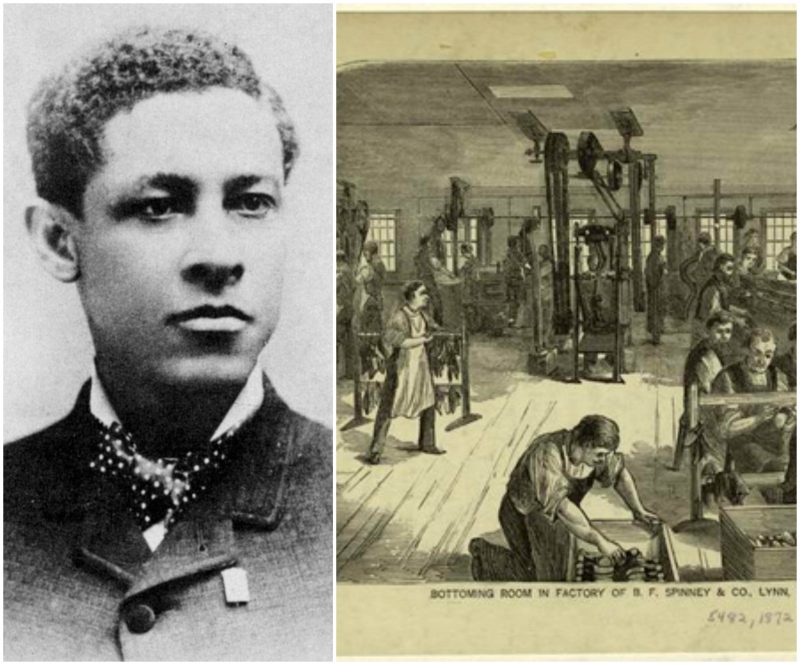

Jan Ernst Matzeliger, the inventor of the groundbreaking “lasting machine,” is solely responsible (no pun intended) for revolutionizing the shoe-making industry in the 19th century.

The inventor has been rarely mentioned and sadly, his pioneering contribution went unnoticed throughout the years. To obtain affordable shoes in the 19th century was very difficult and expensive.

This changed thanks to his shoe-lasting machine, which sped up the mechanized process and even boosted employment for the industry.

He was born in Paramaribo, Dutch Guiana (Surinam) on September 15, 1852. His mother was a black woman from Surinam, while his father was a wealthy and highly educated engineer from Holland.

Jan turned out to be a child prodigy, and by the age of ten, he began working in his father’s machine shop.

The time spent in the machine shop was valuable, as he discovered his passion and talent for machinery while under his father’s careful supervision.

Although skilled in engineering, he didn’t pursue a career in machinery at that time. He worked as a sailor at the age of 19, and later in 1873, he settled in Philadelphia, Pennsylvania to work various jobs.

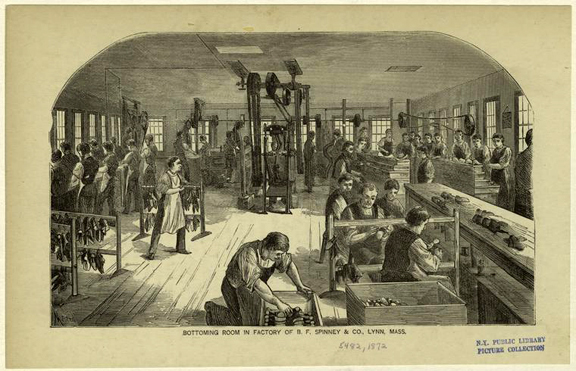

In 1876, the young man quickly learned English and moved to the city of that would become the center of the shoe-making industry, Lynn, Massachusetts.

As a black youth, he had difficulties in finding a profession and his options were very much limited. He later found a job as an apprentice in the Harney Brothers Shoe Factory.

Finally finding a decent profession, he wholeheartedly learned cordwaining, a delicate method of shoemaking by hand. For the shoe to fit, the feet of the customer had to be carefully molded and doubled into stone or wood, shaping a footprint for the “last.”

Later, the shoes were shaped according to the mold. It required skill and a steady hand to tack and sew the two components together. A skilled laster was able to produce 50 pairs in ten hours’ work.

The time-consuming process of handcrafting shoes was deemed too difficult, so Matzeliger had to think fast.

Knowing that the greatest obstacle in shoe making was the sewing and tacking of the soles, Matzeliger set out to find a solution to this problem. There had to be a way to automatize the whole process of lasting, so he began experimenting with designs that could prove useful.

After a couple of prototypes, he was able to patent a “lasting machine” that was crudely made out of cigar boxes, wire, and elastic.

On March 20th, 1883, Matzeliger received the patent no. 274, 207 for a “Lasting Machine.”

The lasting machine was quickly accepted and already started making things easy for the shoe business in Lynn and Matzeliger received more patents to further improve the efficiency of the machine.

The astounding innovation could stitch the leather and sole at a rapid pace. The process that was once painstaking, was now reduced to simple automation, making up to 700 pairs of shoes a day, in contrast to the hand-made 50 pairs a day.

Lynn was dubbed the “shoe capital of the world,” and Matzeliger became a founder of the Consolidated Lasting Machine Company, thanks to his genius design. The halved toil and effort for making shoes resulted in the boost in employment and many workers flooded the industry.

In fact, they didn’t even require training to work the shoe-making machines.

Unfortunately, due to his tireless undertaking and unusual work habit, Matzeliger caught a cold and then contracted tuberculosis. His relentless effort trying to figure out a working design for the revolutionary machine, and spending many sleepless nights on the project, seriously weakened Matzeliger.

He enjoyed the fruits of his labor for a very short time and died in Lynn at the age of 36, on August 24th, 1889.

Matzeliger received his well-deserved recognition when the U.S. Government issued “Black Heritage” postage stamps of his accomplishment on September 15th, 1991. Jan Ernst Matzeliger’s highly underrated invention was perhaps “the most important invention for New England.”

Furthermore, it is considered as “the greatest forward step in the shoe industry,” according to the First Church of Christ bulletin, during the 1967 commemoration (the same church that took him as a member).

Because of the color of his skin, he has been rarely recognized for his contributions and was not mentioned in history until recently.

Although never seeing the full potential of his revolutionary invention, Matzeliger’s creation undoubtedly broke ground with his invention, and significantly lowered shoe prices, making them finally within financial reach of the 19th century working man.